At Shimogawa Orimono, 20 looms are in operation. Ten looms are lined up in two rows, and the weaver operates while looking at the looms on both sides alternately.

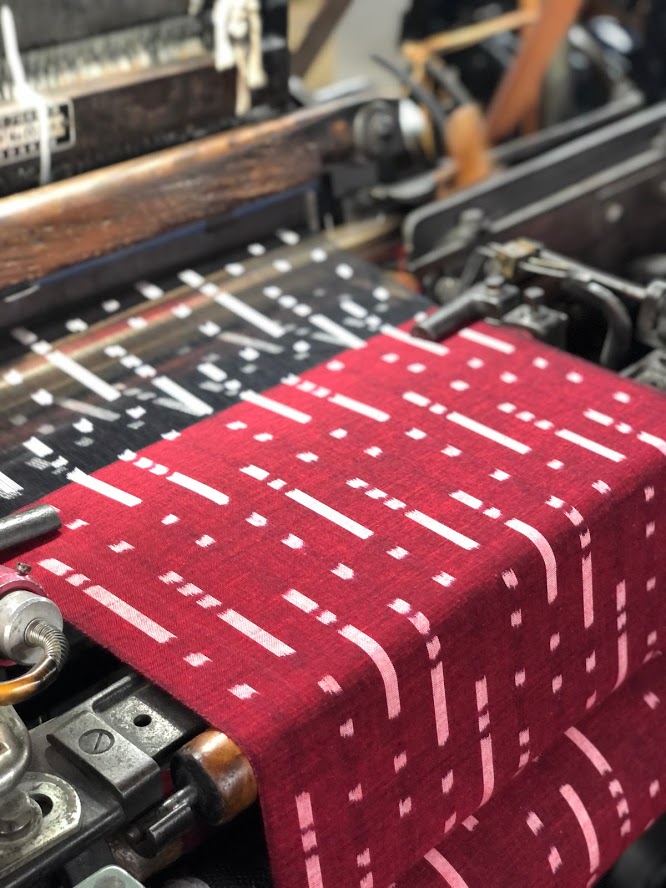

A loom called a shuttle loom needs to be replaced with the next woodwind when the weft wound around the woodwind is exhausted. In addition, weaving is done while correcting the slight deviation of the Kasuri pattern, so the number of units that can be fully operated by one person is limited.

“Tate-Kasuri”, “Yoko-Kasuri” and “Tateyoko-Kasuri” will each learn the techniques related to weaving, and in addition, we will also weave solid colors and stripes. The length of the weft wound around a woodwind varies depending on the thickness of the thread and the shape of the woodwind. Most of the people who come to the factory tour feel that the loom is constantly moving, but the weavers who operate inside are busy moving around.

Shimogawa-Orimono

E-MAIL info@oriyasan.com

URL oriyasan.com

instagram http://instagram.com/shimogawakyozo/

facebook https://www.facebook.com/shimogawaorimono

Twitter @kasuritter

Tumblr kyozoshimogawa

YouTube https://www.youtube.com/channel/UCOZennIqkscFGNJLwnTOyKg