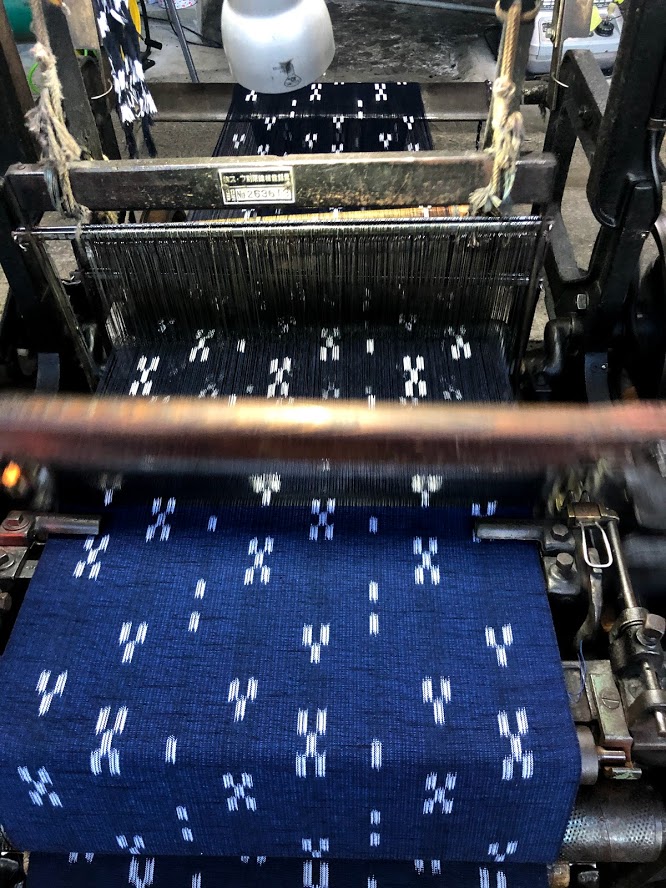

Kasuri looms are old-fashioned looms called “shuttle looms”. Weft threads are wrapped around a woodwind and set in a wooden tool called a shuttle. When this shuttle reciprocates, the weft crosses the warp to complete the woven fabric. Since it becomes a woven fabric with the minimum necessary tension and relatively low movement, it is possible to make a fabric with a soft texture.

There is a device that automatically stops just before the thread wound around the weft thread runs out. It is a device called “Kodenkan”. Kodenkan has a lamp on the red cylinder. On the other side of Kodenkan is an L-shaped wire called “Nuki-stop”. This is a device that automatically stops if the weft thread breaks in the middle for some reason.

When the weft runs out and the loom stops, the weaver replaces the woodwind and starts the loom again. The woven fabric is completed by constantly repeating the work of replacing the weft threads in this shuttle. If the weaver is picked up by another loom and left unattended, the loom will remain stationary and will not move 1 mm. Therefore, another craftsman performs daily maintenance of the loom so that all the looms can operate smoothly without any trouble. This is a linked play.

Shimogawa-Orimono

E-MAIL info@oriyasan.com

URL oriyasan.com

instagram http://instagram.com/shimogawakyozo/

facebook https://www.facebook.com/shimogawaorimono

Twitter @kasuritter

Tumblr kyozoshimogawa

YouTube https://www.youtube.com/channel/UCOZennIqkscFGNJLwnTOyKg